When it is appropriate, renovation can provide a compelling alternative to traditional roofing methods that is cost-effective, customizable, and minimally disruptive to occupants. All images courtesy of ICP.

By Erika Fredrickson

Recognizing the Opportunities for Restoration

How to Assess and Implement the Right Roofing Approach

CE ARTICLE

Sponsored by:

AIA Course: #BE0823I

Earn: 1 AIA LU/HSW; 1 IIBEC CEH

To complete the quiz and receive a certificate of completion, follow this link: continuingeducation.bnpmedia.com/BE2023ICP

Learning Objectives:

After reading this article, you should be able to:

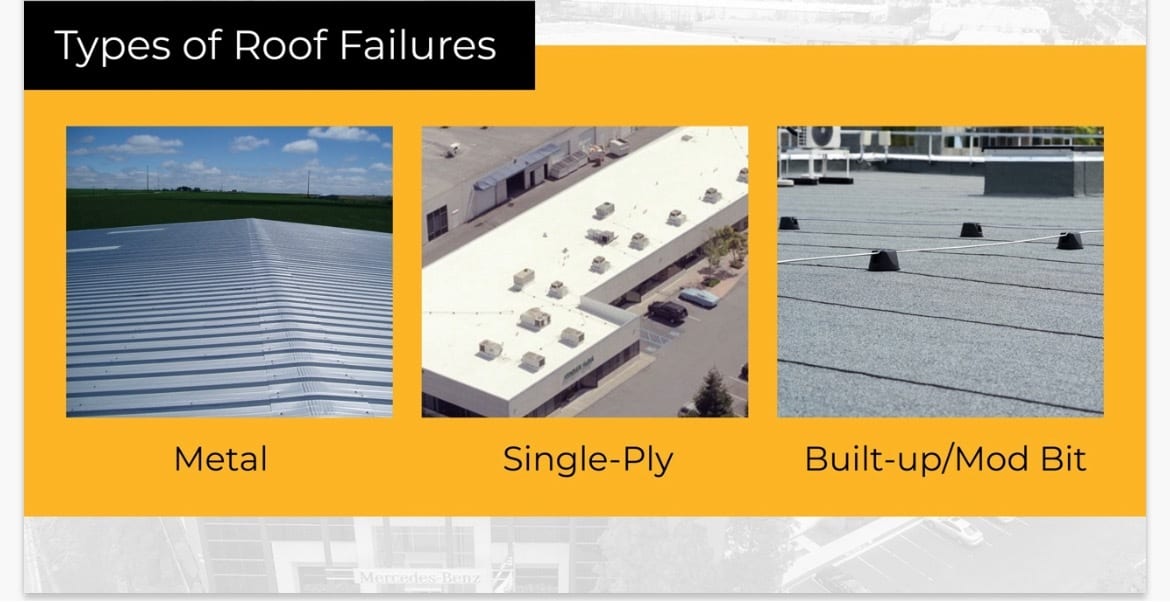

- Describe the common failures associated with single-ply, built-up/asphalt, and metal roofing types.

- List the pros and cons of repairing, restoring, recovering, and re-roofing and how to identify which approach to take.

- Explain best practices for restoration associated with single-ply, built-up/asphalt, and metal roofing types.

- Discuss the important codes associated with restoration along with opportunities presented through the Inflation Reduction Act.

Commercial roof restoration can present a viable, cost-effective, and environmentally sustainable solution, particularly when a complete tear-off is impractical or unnecessary. In this article, we will discuss the ways in which commercial roofing fails and the process of evaluating whether restoration is the right choice for the project. We will explore key factors to consider when conducting a comprehensive roof assessment as well as delve into important considerations following the initial evaluation, such as project timing, prioritization in relation to other business projects, and future expansion plans. We will discuss the specific steps involved in achieving a proper and durable roof restoration and list applicable codes and opportunities associated with the Inflation Reduction Act. By embracing these practices, you can enhance the longevity of your building, ensuring genuine sustainability while recognizing that roof coatings and restoration methods may not be suitable for every structure. This comprehensive approach empowers you to make well-informed decisions regarding your roofing needs.

It is essential for contractors and building owners to discern when renovation is appropriate and when more extensive measures are necessary.

Renovating a roof brings a range of advantages that set it apart from traditional repair, recovering, or reroofing methods. It can offer a cost-effective solution, as it typically requires less material and labor compared to complete replacement. It also allows for customization and aesthetic enhancements without too much invasive work. Additionally, renovating a roof can often be completed with minimal disruption to the occupants, reducing the inconvenience and hassle associated with extensive construction projects. When it comes to addressing roofing issues, renovation can often emerge as a compelling choice, offering a reasonable alternative to complete recovering or reroofing.

However, for contractors and building owners alike, it is crucial to discern when renovation is a viable solution or when it is better to opt for more extensive measures. Understanding the key indicators and factors that determine the feasibility of renovation versus other options is paramount, ensuring that roofing systems receive the appropriate treatment they require. In this section we will look at a few different types of commercial roofing materials and the unique failures and issues they can experience over time and discuss solution basics. By recognizing the specific vulnerabilities associated with different roofing types, contractors can accurately evaluate whether renovation is a suitable option.

High humidity, saltwater exposure, acidic rain, and chemical pollutants can speed up the metal's decay, leading to weakened structure, leaks, and perforations in the roof.

Metal Roofing Failures

Metal roofing is a popular and durable roofing option known for its longevity, strength, and versatility. It has high-level resistance to various weather conditions, including strong winds, heavy rain, and snow. Metal roofs are also fire-resistant, providing an added layer of safety and protection. They tend to be low maintenance, requiring minimal upkeep compared to other roofing materials, and they are less susceptible to rot, insect damage, and mold growth.

Additionally, metal roofs are energy-efficient, as they reflect sunlight, reducing heat absorption and keeping the building cooler in warm climates. This can contribute to lower energy costs for cooling. In general, metal roofs are considered environmentally friendly, often containing a high percentage of recycled materials and being fully recyclable at the end of their lifespan. Each type of metal roofing has its own unique characteristics, advantages, and considerations.

While metal roofing is known for its durability and longevity, certain failures or issues can still occur. Although metal roofing materials are generally resistant to corrosion, prolonged exposure to certain environmental conditions can lead to corrosion over time. Factors such as high humidity, saltwater exposure, acidic rain, or chemical pollutants can accelerate the corrosion process. Corrosion can weaken the metal, compromise its structural integrity, and eventually lead to leaks or perforations in the roof.

Metal roofs are typically secured with fasteners such as screws or nails. Over time, these fasteners can become loose or even dislodged due to factors such as expansion and contraction caused by temperature fluctuations or the movement of a building’s structure. Loose or missing fasteners can cause panels to lift, resulting in gaps that allow water infiltration and wind damage.

In standing seam metal roofs, where panels are connected by interlocking seams, seam failure can occur if the seams are not properly installed or if the metal undergoes excessive movement. Seam failure can lead to water penetration and subsequent leaks.

Metal roofing materials expand and contract with temperature changes. Over time, this thermal movement can cause stress on fasteners, seams, and other roof components. If the roofing system is not designed or installed to accommodate thermal expansion and contraction, it can result in buckling, warping, or stress fractures in the metal panels.

Another potential issue is galvanic corrosion, which occurs when two dissimilar metals come into contact in the presence of an electrolyte, such as water or moisture. This can happen when incompatible metals, such as aluminum and steel, are used together in a metal roofing system without proper insulation or separation. Galvanic corrosion can lead to accelerated metal degradation and premature failure.

Roofing penetrations such as skylights, chimneys, vent pipes, and solar panels automatically complicate roofing systems by providing a potential entry point for water. If installation and flashing are not done correctly, it can result in leaks and water damage to the roof structure, insulation, and interior spaces.

Single-ply membranes can be vulnerable to punctures, tears, or cuts during installation or maintenance, which can compromise the waterproofing integrity of the roof.

Single-Ply Roofing Failures

Single-ply roofing refers to roofing systems that consist of a single layer of flexible and durable membrane material. This type of roofing offers several advantages, including ease of installation, energy efficiency, and versatility. Examples of single-ply roofing include ethylene propylene diene monomer (EPDM), thermoplastic olefin (TPO), and polyvinyl chloride (PVC).

EPDM is a synthetic rubber membrane known for its excellent resistance to UV radiation, ozone, and weathering. It is flexible, durable, and can withstand a wide range of temperatures. EPDM membranes are commonly available in large sheets that can be mechanically fastened, fully adhered, or ballasted.

TPO is a single-ply membrane popular for its energy efficiency, reflectivity, ease of installation and low cost. It provides excellent resistance to UV radiation, heat, and chemical exposure. TPO membranes are typically available in rolls and can be mechanically fastened, fully adhered, or heat-welded.

PVC roofing membranes are made of a thermoplastic material and offer excellent durability, chemical resistance, and fire resistance. They are known for their ability to withstand harsh weather conditions, including high winds and hail. PVC membranes are available in rolls and can be mechanically fastened or fully adhered. Heat-welding is the most common method of seaming PVC membranes.

When it comes to single-ply roofing, whether the membrane is heat welded or chemically welded, the seam is highly vulnerable to failure. If the seams are not properly installed, sealed, or maintained, there can be major issues. Common issues include open or poorly adhered seams, separation, or seam disintegration, which can lead to water infiltration and leaks.

Single-ply membranes can be vulnerable to punctures, tears, or cuts, which can compromise the waterproofing integrity of the roof. Damage can occur during installation, maintenance activities, or as a result of external factors such as foot traffic, falling debris, or severe weather conditions. Flashings are crucial components of single-ply roofing systems that can also produce problems. Flashings provide waterproofing around roof penetrations, edges, and transitions, but improperly installed or deteriorated flashings can result in water penetration, compromising the roof’s integrity and causing leaks.

Single-ply membranes can be attached to the roof substrate through various methods, such as mechanical fastening or adhesive bonding. If the attachment is inadequate or if fasteners become loose or dislodged over time, it can lead to membrane uplift, billowing, or even complete detachment in severe cases. These systems can also be susceptible to chemical degradation caused by exposure to certain substances, such as oils, solvents, acids, or cleaning agents. Chemical degradation can result in membrane weakening, discoloration, embrittlement, or loss of flexibility, ultimately compromising the roof’s performance.

UV radiation from the sun can gradually degrade the surface of single-ply membranes, especially those without adequate UV stabilizers or protective coatings. UV degradation can lead to the loss of membrane flexibility, cracking, blistering, or deterioration, reducing the roof’s overall lifespan.

As with any roofing system, improper installation practices breed failure. A range of issues with single-ply roofing systems can occur including inadequate substrate preparation, incorrect application of adhesives or seam sealants, improper flashing installation, or failure to follow manufacturer guidelines. These issues also may include poor adhesion, weak seams, or compromised waterproofing.

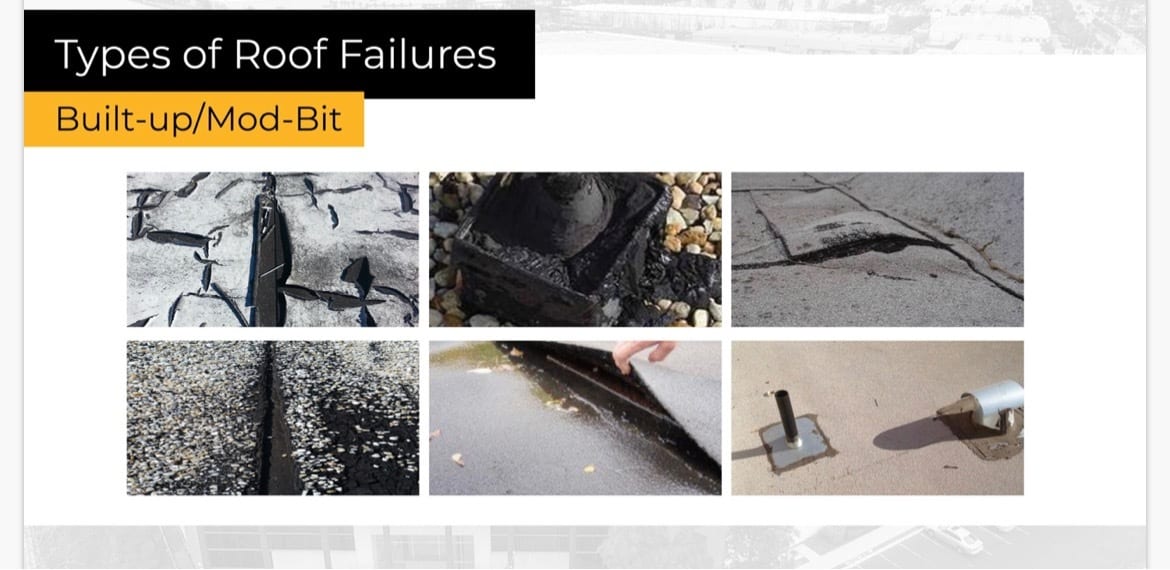

Small cracks on the mod-bit membrane surface—referred to as “alligatoring” can occur due to age, weathering, or UV exposure.

Built-up/Mod-bit Roofing Failures

Built-up roofing (BUR), also known as a “tar and gravel” roof, is the traditional type of flat or low-slope roofing system composed of multiple layers of bitumen (asphalt or coal tar) and reinforcing materials that create a durable and waterproof roof membrane. Mod-bit roofing, short for modified bitumen roofing, is a type of flat or low-slope roofing system that is commonly used in commercial, industrial, and residential applications. It is a modern variation of the BUR system, combining the benefits of BUR with technological advancements.

Mod-bit roofing consists of a reinforced bitumen membrane modified with polymers for enhanced performance. The primary component of mod-bit roofing is the bitumen membrane, which provides waterproofing and weatherproofing properties. This type of roofing provides an effective solution for flat or low-slope roofs, combining the benefits of BUR with improved performance and ease of installation. And while BUR/mod-bit systems are durable, they have their own vulnerabilities.

Blistering is a common issue with mod-bit roofing and occurs when air or moisture becomes trapped between the layers of the membrane. It can be caused by improper installation, inadequate substrate preparation, or excessive heat during application. Blistering can lead to membrane delamination, reduced waterproofing effectiveness, and potential leaks.

Mod-bit roofing membranes have seams where the individual rolls or sheets are joined together. If the seams are not properly installed, sealed, or maintained, they can be prone to failure. Common seam issues include open or poorly adhered seams, separation, or seam disintegration, which can result in water infiltration and leaks.

Another issue is “alligatoring” or cracking, which refers to the formation of a pattern of small cracks on the surface of the mod-bit membrane. It can be caused by age, weathering, or exposure to UV radiation. Cracking can compromise the integrity of the membrane, leading to water penetration and reduced performance.

Ponding water occurs when water accumulates and remains stagnant on the roof surface for an extended period, typically due to inadequate drainage or improper roof slope. Mod-bit roofing systems should be designed to prevent ponding water, as it can lead to membrane deterioration, accelerated aging, and potential leaks. But over time, ponding can occur on even the best-designed surfaces.

Mod-bit roofing membranes can be vulnerable to damage from foot traffic, falling debris, or sharp objects. Punctures, tears, cuts, or abrasions in the membrane can compromise the waterproofing properties of the roof, leading to leaks and potential structural damage.

As with other roofing systems, BUR and mod-bit flashings can become a point of failure. Improperly installed or deteriorated flashings can result in water penetration, compromising the roof’s integrity and causing leaks. In general, improper installation practices can result in a range of issues with mod-bit roofing systems that lead to poor adhesion, weak seams, or compromised waterproofing.

Restoration can be an easier and more cost-effective way to prolong the life of a roof, but it requires that the original roof is in reasonable condition.